- Visitor:51

- Published on: 2025-07-02 04:13 pm

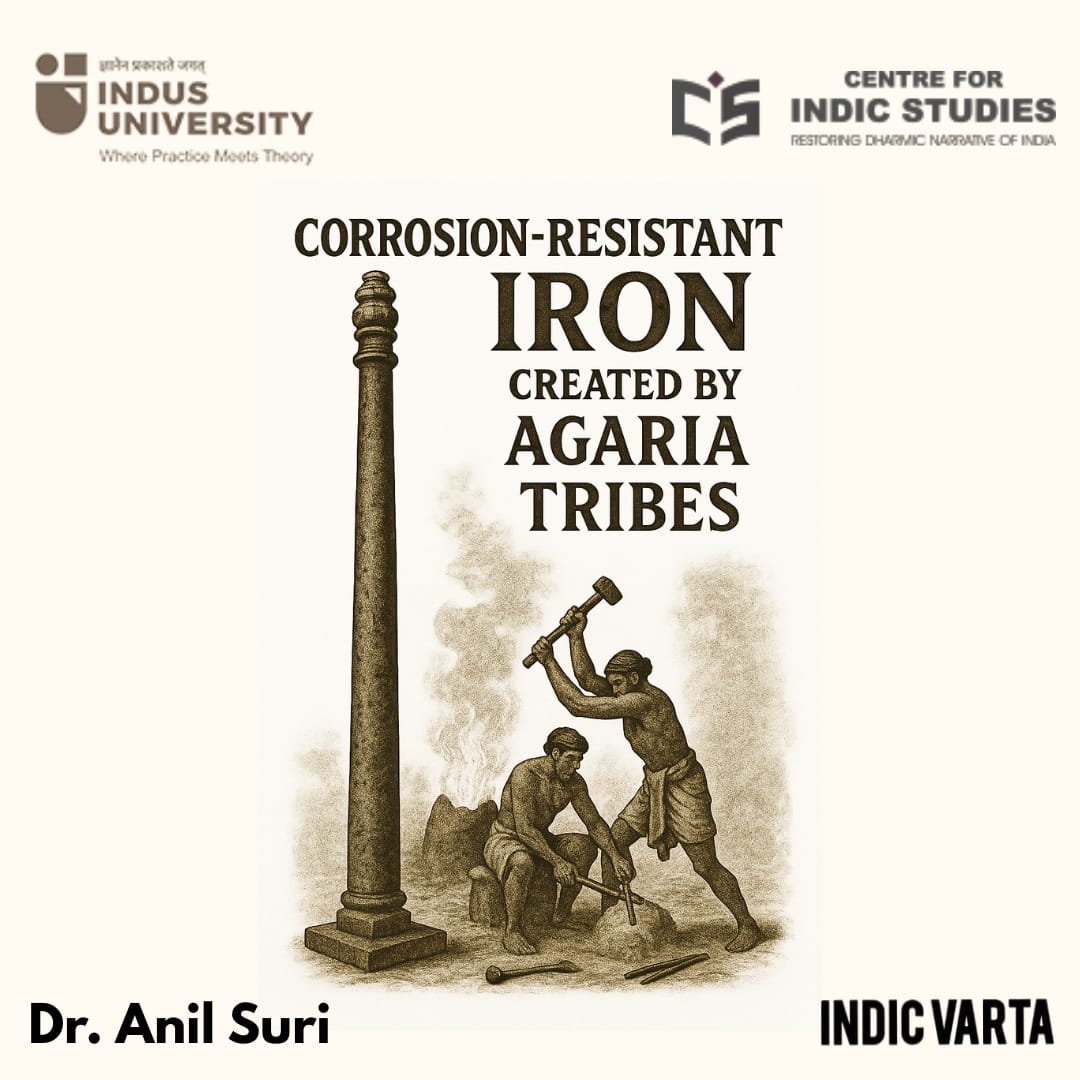

Corrosion - Resistant Iron: The Secret of The Agariya Tribe

The technology for producing corrosion-resistant iron involves incorporating a small amount of phosphorus in the iron, which would then form a passivating impervious layer of iron phosphate on the surface of the iron, shielding the iron from corrosion. The recipe for producing such iron appears to have been well-established by the 5th century CE, as exemplified by the Delhi Iron Pillar in the Qutub Complex in Delhi. Our rudimentary understanding of the rust-resistant behaviour of the Iron Pillar, as well as another fragmented iron column in Dhar, Madhya Pradesh stems from the analysis of Prof. R. Balasubramaniam of the Indian Institute of Technology Kanpur.

However, there is a catch: both these pillars were likely produced during the Gupta period and originated from the same region – somewhere in present-day Madhya Pradesh. Corrosion-resistant iron, though, can be found in many parts of the country and from widely varying times, from the frame of the 13th century Konark temple in Odisha to the 18th century guns in forts built by the Marathas on the Konkan coast. The iron in these instances came from ores from different parts of the country, and the production process used is unlikely to have been the same. Indeed, ethno archaeological studies have highlighted how traditional metal-producing communities of the subcontinent were highly secretive about their knowhow, and did not share it even with their counterparts in adjacent districts. This secrecy was perfectly acceptable: allowing metalworker communities to keep their knowledge secret and thereby profit to the maximum possible extent from the knowhow they had developed with considerable investment of time, energy and money fostered a healthy competition among multiple groups and was a major factor responsible for the emergence of multiple novel technologies and products.

Was phosphorus always the secret ingredient?

The Agariya tribe of Central India were well-known as producers of iron. They produced iron by the bloomery or sponge-iron process, and were capable of producing up to a quintal of iron in a single heat using their traditional process operating multiple furnaces simultaneously. Sadly, thanks to the British clamping down on their industry and assiduously stamping it out, their knowledge has been mostly lost, and hardly any member of the tribe today remembers the details of their traditional process.

Yet, their technology has intrigued modern scientists for long. Recently, a group of scientists from India and Australia made an attempt to understand the corrosion resistance of iron made by the Agariyas by their traditional process, using old samples provided to them by members of the tribe. Their findings threw up a surprise: there was no phosphorus in the iron. In other words, the explanation that the corrosion-resistance of the iron was owing to the formation of a protective phosphate skin on its surface was out.

The trade secret of the Agariyas

Although the surface of the Agariya iron did not contain phosphorus, the scientists noticed that it did contain a very small proportion of a slightly unusual ingredient: titanium. Titanium undergoes segregation, i.e., it does not dissolve in the bulk of the iron and instead precipitates at the surface. Here, it undergoes oxidation and forms titanium dioxide, a highly hydrophobic material and inert material. The hydrophobicity of titanium dioxide prevents water from adhering to the surface, which is a prerequisite for rusting. Also, it is very stable and is itself not damaged by chemical attack. Thus, it forms a passivating layer on the surface of the iron in precisely the same way that iron phosphate does on objects like the Delhi Iron Pillar.

But how does titanium make its way into the iron? A close look at the Agariya iron-making process shows that the iron ore used for making the iron contains a small amount of ilmenite (a combined oxide of iron and titanium with the chemical formula, FeTiO3). Ilmenite is itself today regarded as an important ore of titanium, and is the source of the titanium in the Agariya iron. The Agariyas seem to have worked out that incorporating a small amount of ilmenite in the ore charged into the furnace alters the surface characteristics of the iron and makes it highly resistant to rusting.

This finding suggests that traditional Indian iron-makers used a variety of techniques exploiting typical local resources to produce corrosion-resistant iron. There was no standard recipe followed all over the country. It is probably owing to the diversity of raw materials and processes used to produce the same end-result that the use of such iron had spread far and wide over the subcontinent. One can gauge how commonplace corrosion-resistant iron was from the fact that it was being used even in remote regions. Consider, for instance, the iron dowels used to position pillars (see image) in the Jain temples built in the 15th century in Abhapur in the Polo Forest of the Sabarkantha District in Gujarat. The temples themselves may have been ravaged by invaders, but one cannot fail to spot the undamaged iron dowels protruding from the bases of stone columns that have been uprooted and now lie higgledy-piggledy in the complex.

Above: Dowels made of corrosion-resistant iron protruding from the bases of pillars in the Jain temples of Abhapur, Sabarkantha District. The dowels have been highlighted for clarity.

Implications for the present

Although iron and steels have come to be widely used for engineering applications, rusting is a significant problem. It is estimated that over $2 trillion are spent worldwide annually in combating the corrosion of iron and steel by way of coatings and implementing other strategies to minimize this problem, and replacement of worn-out parts. A detailed study of all available traditional Indian rust proof iron samples may provide solutions to combat the problem of corrosion. Better still, if we are able to reverse-engineer some of these traditional irons, we may come up with alternatives to replace currently used alloys, especially in highly demanding applications such as ships and oil rigs.

- 25 min read

- 3

- 0